Proven Solutions & Services for Phosphorus and Metals Compliance Iron, Aluminium, Alkalinity

Wastewater Parameter Monitoring and Control:

Does your plant measure up to new regulatory requirements?

Water companies across the UK have increasingly stringent requirements for compliance at wastewater treatment works. The largest subset of these, relates to chemical phosphorus removal. Water companies in England and Wales have already invested considerable sums to meet existing requirements and new investment periods across the UK will see even tighter regulations for both phosphorus and metals compliance.

Hach can help you achieve compliance certainty.

Since 1933 water quality has been our focus. Hach® is ready to aid you in meeting customer demands for affordable and resilient service whilst fully meeting wastewater compliance objectives.

Our proven instrument, systems, and service for ortho and total phosphorus, alkalinity, total iron, aluminium and trace metals parameter monitoring can be enhanced further by the use of real-time-control (RTC) to ensure compliance.

Easy, Affordable—and More You May Not Know About RTC-P

With more than 1500 installs across Europe since 2012, RTC modules offer a proven solution for wastewater monitoring and output control that is affordable, easy to install and easy to use across multiple sites.

Learn More

AMP8 and SR27 will be the most ambitious wastewater investment programmes yet.

During this AMP cycle, and SR27 to follow in Scotland, municipal wastewater companies will be responsible for maintaining phosphorus consents of <0.1 mg/L in some cases while keeping water bills as affordable as possible.

Contact us

Spotlight on Key Parameter Monitoring

Reduce capex and carbon emissions with Hach’s phosphorus real time control system. Historical plant performance need not reflect what is really achievable with existing assets and advanced control. More information.

Phosphorus - the most common cause of water quality failures in the UK. More than 50% of rivers and 75% of lakes currently exceed the set standard for phosphate levels.

Hach understands the challenges that water companies and their partners face during current investment periods such as AMP8. The costs of failing to meet rigorous consents for parameters such as phosphorous or iron are far higher than the investment in continuous monitoring solutions. Consequences of insufficient chemical phosphorus removal can include steep fines levied by Ofwat and other environmental regulators, fish kills or algae blooms that impact community water sources, as well as negative impacts on the reputation of the water utility as a neighbour, employer and brand.

Hach can help you in realising a return for your investment by robustly controlling eutrophication and limiting your phosphorus discharge to safe and compliant levels within the Water Framework Directive. We can also help you measure and ensure compliance with iron or other metals as a result of the use of metal salts for chemical phosphorous removal.

| Tight | Moderate | High |

| | | |

| Segment | Tertiary treatment

(Actiflo, CoMag etc.) | Tertiary treatment

(Meccana) | With TT | Without TT |

| P-Limit | < 0.4 mg/l | 0.4-0.8 mg/l | > 0.8 mg/l |

| Hach Solution | P-RTC, Filtrax

Low range Phosphax

Total suspended solids | P-RTC, Filtrax

Medium Range

Phosphax | P-RTC, Filtrax

Medium Range

Phosphax | P-RTC, Filtrax

Medium Range

Phosphax + TSS |

Solution: RTC-P provides compliance certainty in 5 simple steps

1. INVEST » 2. INSTALL » 3. COMMISSION » 4. OPTIMISE » 5. COMPLY

Since 2012 more than 1,500 standardised RTC-P control modules have been successfully installed on more than 800 sewage treatment plants with a load of just a few 1,000 PE up to 6 million PE.

With the correct combination of controllers, analysers, and communication capabilities, standard RTC installs in continental Europe and the UK have proven that quick, decisive and consistent parameter control is possible at previously unheard-of levels.

With a turnkey solution and Hach support, even the most ambitious AMP8 or SR21 compliance goals are within reach.

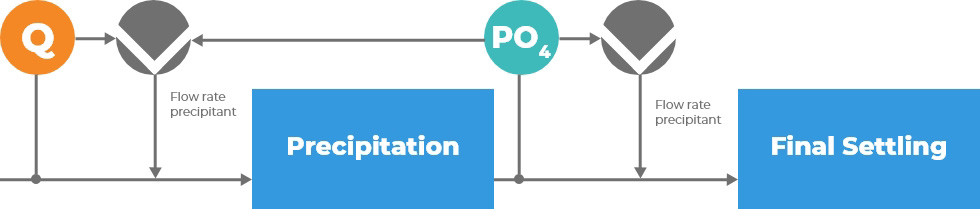

How it works: RTC-P is feed-back and feed-forward in one

Hach’s load-based RTC-P system gives you more insight into your operations by providing two chemical dose signals from a single phosphorus measurement point.

RTC-P optimizes chemical phosphorus removal by adjusting chemical dosing in real time through the continuous measurement of phosphate concentration and flow. By maintaining consistent effluent phosphorus levels and enhancing your chemical phosphorus control system, RTC-P enables phosphorous compliance certainty around the clock.

Once the system is programmed with a PO 4-P setpoint, it continuously measures PO 4-P concentration and wastewater flow rate, calculating the minimum amount of precipitant required to match the biological phosphorus uptake. The system will automatically switch to fallback strategies if input signals inflow or PO 4-P are not available.

Advantages include:

Maintaining minimum phosphorus level for biological requirement

Providing auto polish for a secondary dose point

Balancing phosphorus removal across the plant for chemical efficiency

| Model | Application | Input Parameter | Output | Benefit |

| RTC-P | Chemical

phosphate

removal | PO4-P, Qln | QPrecipitation | Maintain compliance based on stable PO4-P discharge values, reduced precipitant consumption and less precipitation sludge, improved acid capacity |

Because it is hosted by specific hardware, RTC-P software easily combines with other control modules.

CASE STUDY: Phosphorus outlet reduced 45% (to 0.23 mg/L) in German WWTP with annual volume of 2.3M m3

The results were immediate and dramatic with the installation of the water intelligence system, with reductions in all parameters measured in the outflow, and in energy consumption in bio tank blowers.

Download Case Study

CASE STUDY: Daily fluctuation delta reduced from .6 to .35 mg/L in Swiss WWTP with annual volume of 5.9M m 3

“The module has now been operating at our plant for almost three years without any problems. Using the latest software, it now works even better than before and fully meets my expectations.”

Download Case Study

APPLICATION NOTE: Improving Compliance through Real-Time Control

This application note describes a system for real-time control and the benefits it offers, specifically for plants that are controlling phosphorus by chemical dosing with ferric chloride (FeCl 3)

Download the Application Note

Online process solutions for Phosphorus monitoring

Total Phosphorus

Discharge of phosphorus encourages the growth of algae and aquatic plants that rob streams, rivers and bays of oxygen, thereby disrupting the ecosystem. Get accurate, continuous phosphorus monitoring at values as low as 0.01 mg/L, with optional nitrogen or phosphate measurement capabilities.

Explore the EZ Series Phosphorus Analysers

Online process solutions for Iron & Aluminium monitoring

Total Iron and Aluminium

To protect the environment from excessive wastewater chemical application, Ofwat commonly allies phosphorus permits to iron and aluminium limits. These metal limits can represent even greater challenges than the phosphorus limit itself. To manage all risk associated with phosphorus permits we have a range of metal analysers to provide accurate, continuous monitoring for up to 8 streams.

Explore the EZ Series Iron Analysers

Explore the EZ Series Aluminium Analysers

Alkalinity

Alkalinity

Dosing of highly acidic ferric sulphate for phosphorus removal can place high demand on sewage alkalinity, dropping pH and inhibiting ammonium treatment. Composite samples often mask the true risk associated with chemical dosing, where peak application rates typically coincide with maximum ammonium concentrations. Continuous alkalinity measurements show true process risk and used in conjunction with Hach RTC strategies protect your biology in accordance with the Water Framework Directive.

Explore the EZ Series Alkalinity Analysers

Everything you need to prove that your plant is achieving consents in minutes

Test for all of the relevant parameters at a fraction of the cost

For some facilities, buying a process analyser for every parameter doesn’t fit the budget. Instead, customise a Lab in a Box solution and get everything you need—from benchtop instruments to test kits, chemistries and supplies—for fast, accurate results throughout the investment cycle.

Recommended parameters for wastewater treatment plant compliance

Phosphorus

Iron

Aluminium

Alkalinity

Trace metals: zinc, nickel, copper, lead, chromium, cadmium, mercury

Never run out of supplies

With Pick-and-Ship, you can schedule recurring deliveries of consumable supplies so that you’re always minutes away from compliance results.

Support across all 5 steps of analysis

Sample Collection

Protocol for each test and sample type to ensure a representative sample.

Sample Preparation

Avoid common errors in pH adjustment, filtering, dilution or digestion.

Use of Standards

Accuracy check and instrument calibration for every range of analysis.

Procedure

Easy to follow with limited analytical skills. Procedures are complemented with intuitive menus on all our spectrophotometers.

Interpretation

Support for taking action based on clear analysis.

See Your Regulatory Compliance Picture 24/7

Hach offers a range of solutions to meet regulatory changes to wastewater parameter monitoring as required by new stricter consents and other regulations, including Real-Time Control (RTC), a complete turnkey solution that enables you to see your full compliance picture on a continuous basis.

Why RTC?

Phosphorus compliance certainty 24/7

RTC modules combined with process measurement technology can immediately react to load peaks in the inlet to the sewage treatment plant and guarantee a consistent effluent quality.

Minimal capital investment

A standard RTC-P install can bring your phosphorus within the approved Water Framework Directive range for less than you may think.

A standardized system

The RTC modules can be quickly integrated into an existing automation structure without much effort. Standardised control algorithms eliminate cost-intensive on-site software testing during PLC installation, and a Hach Service plan can ensure that the transition is seamless and safe.

Seamless coordination

Hach supports planners and system integrators through the project management cycle, providing:

Tender documentation

Guides for installation and commissioning

Application-specific consulting

Customised training sessions

Visibility into multiple sites

RTC enables live performance monitoring so that unmanned and remote sites benefit from the same level of attention and precision control.

Ease of use

Our priority is to ensure that your focus is on delivering service, not attending to software and hardware issues.

Ongoing support

A complete Service package includes local field service experts to provide routine maintenance visits and warranty repair, plus a team of remote technical experts with the ability to monitor your system to ensure optimum performance. It's like having a Hach Technician right there with you at the facility.

Learn More

Ensure smooth commissioning with Hach Service

At Hach we understand that water companies across the UK face unique challenges in addition to stringent regulatory oversight, so we have developed Hach Service Plans to help you navigate commissioning and troubleshoot operations issues.

Even though Hach hardware and software products are user-friendly and easy to maintain, operators have demonstrated better results right away—and even more optimised gains over time—when Hach’s expert service team is involved.

We offer a range of service levels with increasing coverage for the entire lifecycle of your equipment.

Learn More

Have Questions? We Have Answers!

Contact us for tech support, service, sales, or to get a quote.