Hach® designs, manufactures and distributes world-class instrumentation, test kits and reagents for testing water and product quality in a variety of beverage industry applications. Our products can be used within influent, in-line and at-line, as well as clean-in-place (CIP) and effluent water treatment. From beer to soft drinks to bottled water and wine, Hach can help you meet the beverage quality control demands at your facility.

The right analytics solution can help you ensure that products comply to specifications and meet shelf life requirements. Production process optimization, water conservation, environmental profile improvements and regulatory compliance all are benefits of analytics.

Measuring at the right time and with the best accuracy goes far in improving beverage outcomes and our controllers, sensors and analyzers are designed to help you optimize your process from start to finish.

![]()

From craft breweries to large breweries, quality, flavor stability and shelf life are critical to brand and business. For continuous and reliable quality control in the production process, at line or in the lab, from incoming water through to final package, Hach has the beverage measurement and testing solutions you need.

![]()

Hach allows vintners to ensure product quality, while protecting flavor stability and shelf life. From SO₂ and dissolved oxygen to total package oxygen, you can find a variety of wine analysis tools at Hach.

![]()

Accurate bottled water analysis and testing is made simpler with solutions for carbon dioxide and ozone measurements. From carbonated to still water, our wide range of quality control solutions ensures your bottled water continues to meet high standards.

Hach works with beverage manufacturers to provide a number of quality control tests that measure oxygen and carbonation levels in soft drinks. We strive to ensure that you produce the best product quality time and time again, both at line and in the lab.

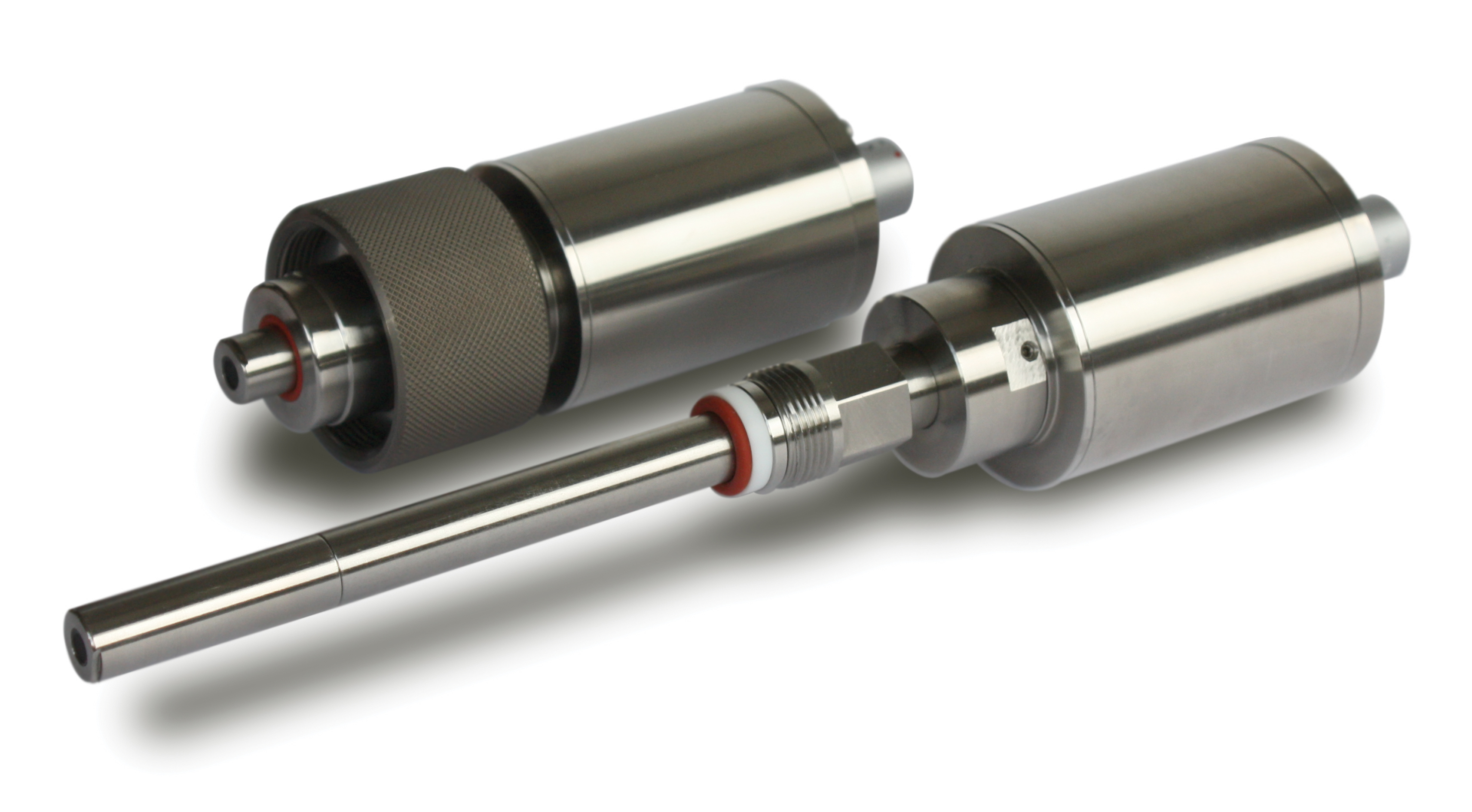

The Orbisphere 3650/3655 offers a robust portable, complete solution system for dissolved oxygen measurement.

Designed to be used with Orbisphere high quality oxygen sensors, these instruments provide accurate and quick measurements in both the dissolved and gas phases.

Designed for the harsh environments of breweries and seamlessly adapted for laboratory or verification purposes in the power generation, electronics, life sciences and other similar beverage industries.

The most rugged portable oxygen analyser in the industry.

With Luminescent Dissolved Oxygen (LDO) technology integrated, the Orbisphere 3100 dissolved oxygen analyser is sure to improve process efficiency and provide accurate dissolved oxygen measurements.

Designed for use in the beverage industry for both laboratory and process environments by measuring dissolved oxygen at ppb level.

Precision to 0.8 ppb and limit detection of 0.6 ppb with a 2s measurement frequency — Essential to control low oxygen levels in brewing.

The absence of membrane and electrolyte allows sensor accuracy to remain unaffected by process changes or pressure shocks, reducing operating costs. The M1100 Luminescent Dissolved Oxygen Sensor is designed with mechanical robustness and resistance to CIP processes, extending operational lifetime and optimising total cost of ownership.

Designed for professionals, the Hach DR6000 supports brewers in calibration routines, quality assurance, and the development of customized applications. This advanced UV-VIS spectrophotometer offers high-speed wavelength scanning across the UV (ultraviolet) and Visible Spectrum and comes with 250 pre-programmed Hach methods to meet all your beverage analysis needs, including regulatory compliance.

Optimised for safe processes and consistent, quick and accurate water analysis results.

The DR3900 is a benchtop visible spectrum (320 - 1100 nm), split beam spectrophotometer with over 220 pre-programmed methods optimised for laboratory water analysis. With your daily routine of water analysis in mind, the DR3900 spectrophotometer is optimised for safe processes and accurate results.

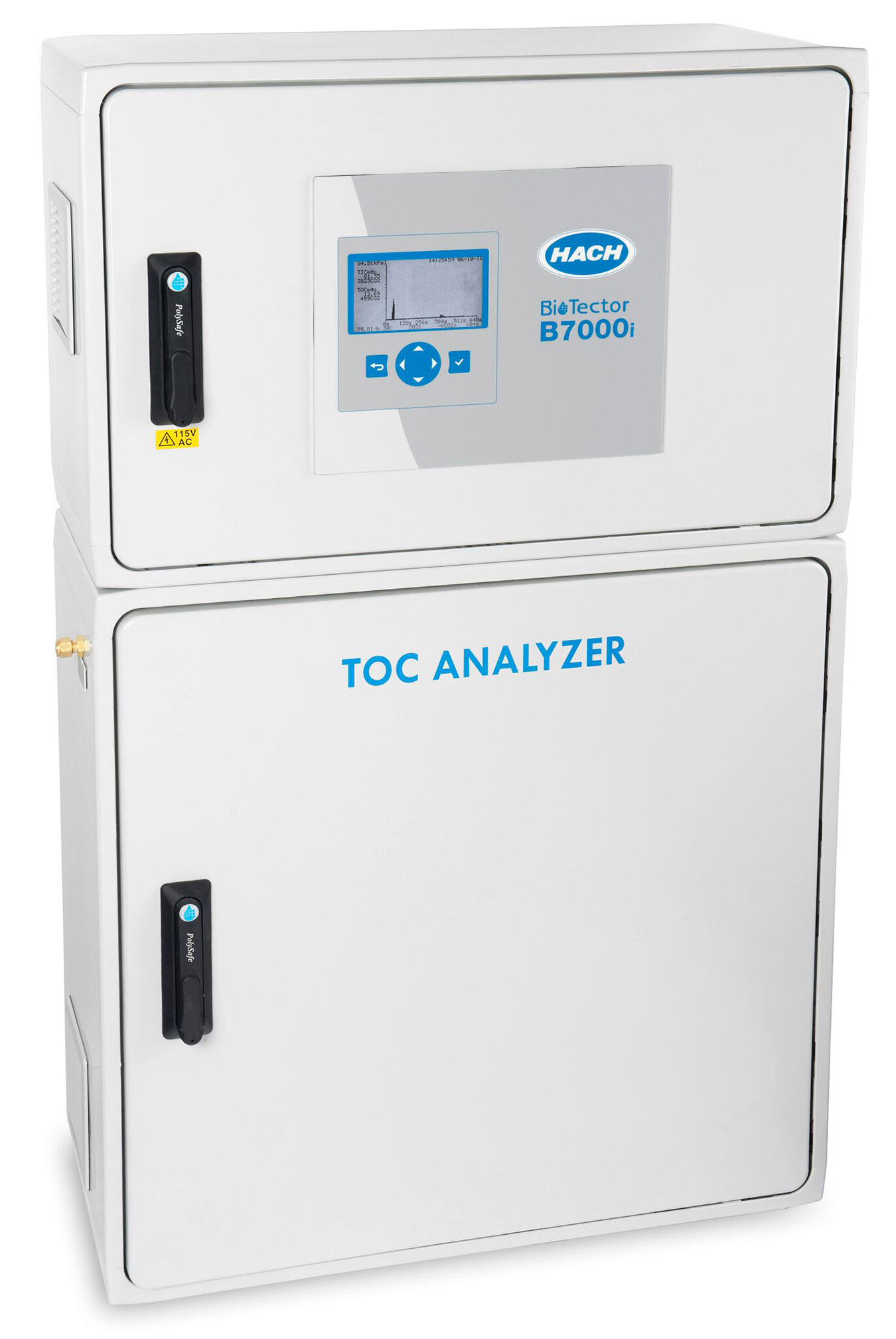

Meet your ideal online TOC Analyser. Able to achieve precise results, even for your most challenging applications.

Hach BioTector TOC analysers with self-cleaning oxidation technology provide maximum uptime and reliability. An innovative analyser that easily handles difficult samples and significantly reduces maintenance. BioTector TOC analysers eliminate build up issues from salts, particulates, fats, oils and greases that lead to measurement drift and high maintenance costs. Optimise your processes to decrease overall plant operating costs. The most advanced system in its class, BioTector products achieve precise results from the simplest to the most demanding applications.

he smart choice for accurate and reliable online process pH measurement

General Purpose Online Process pH Sensor with Integrated Digital Electronics for "Plug and Play" with Hach Digital SC Controllers - pHD Technology, Glass pH Electrode, PEEK Housing, Convertible Mount, 10 m Cable Connects to Claros, Hach’s innovative Water Intelligence System. Seamlessly connect and manage instruments, data, and process from anywhere, anytime, with Claros.

Digital Electrochemistry: Confidence in pH & ORP

Laboratory single channel meter for pH, mV ORP/Redox. Basic instrument without electrodes. The digital meter/electrode system HQD combines reliability, flexibility and ease of use. Interchangeable INTELLICAL electrodes are recognised automatically and store all relevant data.

A robust and portable single-channel pH/ORP meter designed for field use. USB data transfer capabilities.

The HQ1110 Portable Multi Parameter Meter is designed to perform pH, ORP and mV analysis in both field and lab environments. Comes complete with a high-quality DPD1P1 pHD sc pH probe to collect accurate measurements, manage data, and easily review results, nearly anywhere, all within a IP67-rated device.

Contact us for tech support, service, sales, or to get a quote.